Research Papers - 2019: Publications: American Welding.

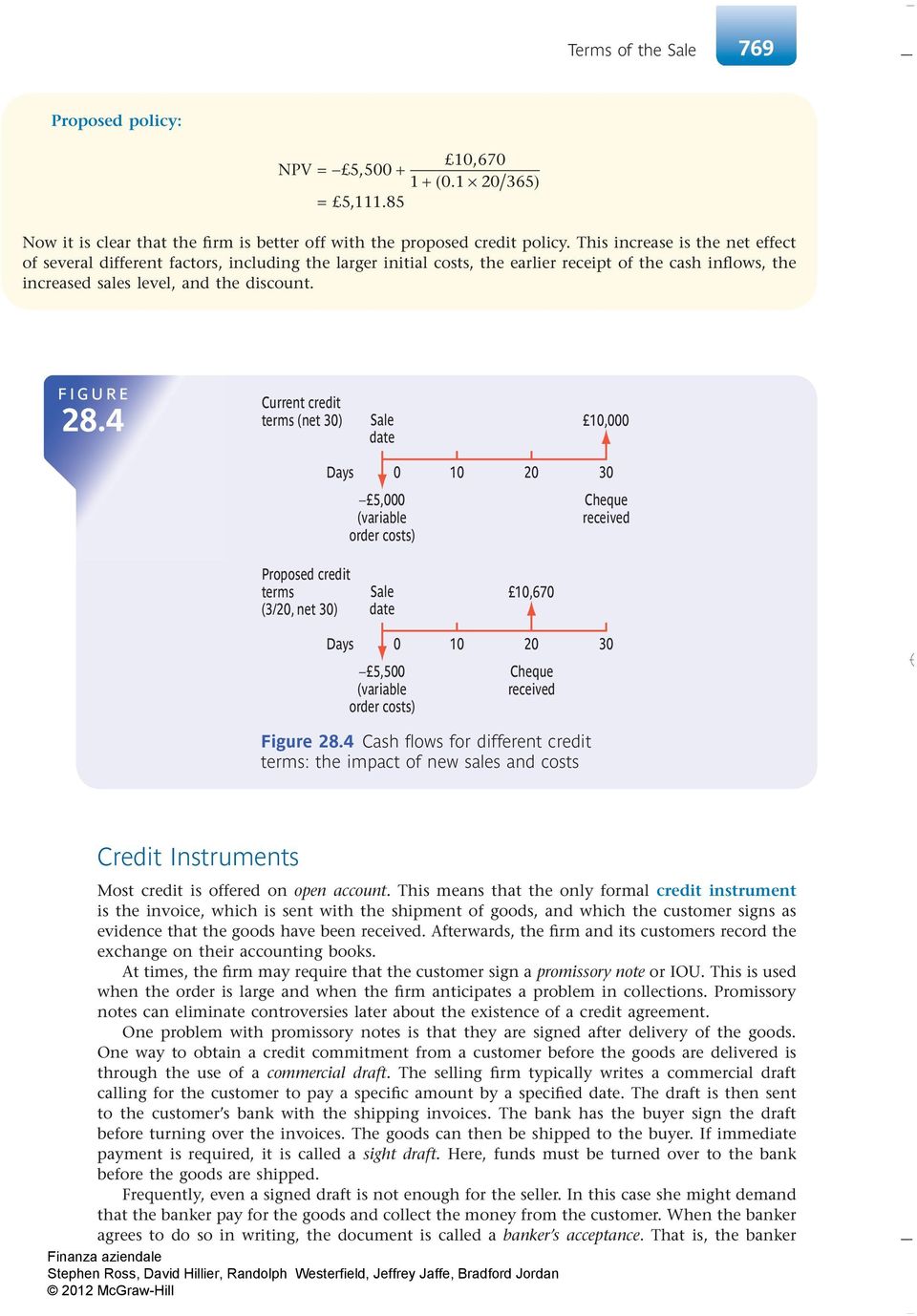

Literature review starting with the research topic of the modeling and analysis of resistance spot welding on galvanized steel sheet used in car body manufacturing. In the process analysis of resistance spot welding on galvanized steel used in vehicle body manufacturing, the quality of spot weld is checked from the tensile strength and shear strength properties of the spot weld. The four.This paper reviews the re search trends in modeling of the resistance spot welding process. Resistance spot welding (RSW) modeling in general a nd prediction in particular, have been a main topic in research for the last few decades, but although the information is quantitatively enormous, it is also pread widely in the literature, and difficult to find. In this work, a review has been carried.Resistance spot welding is a process where the surfaces of the metals are joined together by heat generated by resisting the electric current. This is a relatively old process in welding which came into existence in the 1900s. This process is adopted widely for welding purposes. The main aspects are the pressure applied to the metal surfaces, the electric current passed through the electrodes.

This article presents a report on an electromotive force that appears in the electromagnetically open circuit during resistance spot welding. We measured the potential drop between the Cu electrodes during the supply of an alternating current while keeping the area surrounding the electrical lines available for the potential drop measurement. We detected a unique electromotive force in the.This allowed them to model the link between nugget size and strength along with resistance spot welding and expulsion. Huys’ latest co-authored resistance welding article can be found in the August 2019 edition of the Welding Journal, or on our welding research page under optimizing welding parameters.

WELDING RESEARCH WELDING JOURNAL 123-S ABSTRACT. An expulsion model has been developed for resistance spot weld- ing, based on consideration of the interac-tion between mechanical and metallurgi-cal processes during welding. An expulsion criterion is proposed by com-paring the electrode force with that from the liquid nugget; expulsion occurs when the latter exceeds the former. An effective.